ONLINE ORDERS GET FREE SHIPPING!

Free Shipping

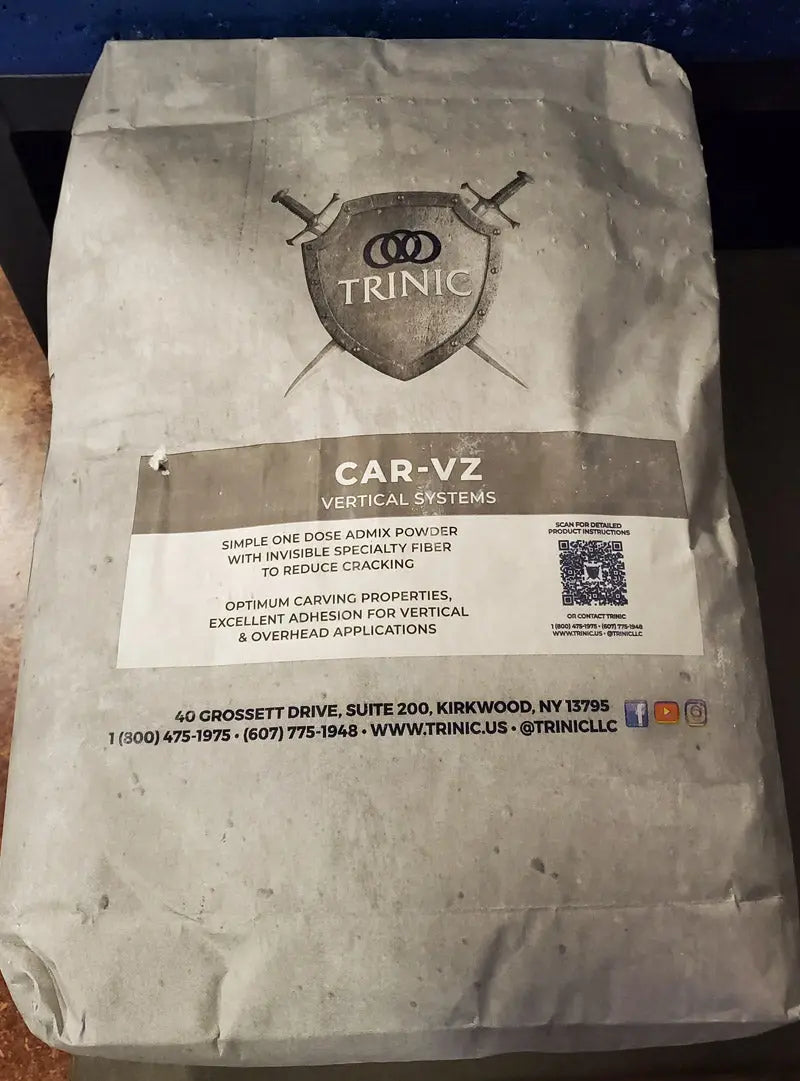

Free Shipping applies to most items on our site- some products are excluded and will state this on the product page (mostly just heavy bags of concrete mix). Free shipping is to US 48. Other areas will get a discounted shipping rate at checkout to compensate.