GFRC AR Glass Scrim Fabric Fiberglass Reinforcement Mat

Size:

Size

Quantity:

Fast Ship: Usually takes 1-2 business days to ship out.

Ships from Oregon (Click for average Ground delivery map )

)

Ships from Oregon (Click for average Ground delivery map

)

)

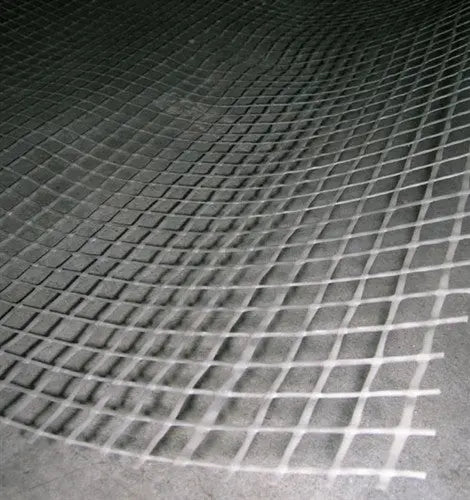

GFRC AR Glass Scrim Fabric Fiberglass Reinforcement Mat

- Nippon manufacturer ARG scrim for concrete and GFRC

- Alkali resistant glass fibers, woven into a 'net'. Scrims are oriented continuous fiber fabrics. The continuous fiber is usually yarn or roving. The continuous strands are not inter-woven, but are laid over each other at ninety degree orientation and then a binder is applied which holds the fabric structure in place.

- Highest zirconia content fiber available. Zirconia is what makes the glass fiber alkali resistant. The higher the zirconia content the better the resistance to alkali attack. This AR Scrim also has excellent acid resistance, and in PVC coated.

- Sold in 5, 10, and 20 linear feet pieces, or by the roll of 300 linear feet and are 36" wide.

- Scrim can be placed in GFRC and wet-cast concrete to greatly increase the flexible strength.

- Ideal way to reinforce around difficult mold shapes, such as sink molds and forms.

Specifications GFRC AR Glass Scrim Fabric Fiberglass Reinforcement Mat

- Coverage:

- 5 linear feet sections are 36" wide: 15 sq. ft. total.

- 10 linear feet sections are 36" wide: 30 sq. ft. total.

- 20 linear feet sections are 36" wide: 60 sq. ft. total.

- Full roll of 300 linear feet @ 36" wide: 900 sq. ft. total.

- 10x10 denotes 10mm (3/8 inch) spacing between strands and is the standard size for most GFRC work and concrete countertop reinforcement.

- When laying into concrete or GFRC, keep Scrim 1/2" away from the finished top of the concrete to avoid ghosting the fabric image.

- Standard use: Place one sheet of fabric in the middle of the concrete/GFRC, and another sheet as the last step, then lightly roll or trowel the scrim into the cement.

TECHINCAL SPECS- GFRC AR Glass Scrim Fabric Fiberglass Reinforcement Mat

| Property | Unit | |

|---|---|---|

| Thermal Expansion Coefficient | ×10-6/K | 9 |

| Softening point | ℃ | 830 |

| Density | ×103kg/m3 | 2.8 |

| Tensile Strength | GN/m2 | 1.5 |

| Young’s modulus | GN/m2 | 74 |

| Strain to failure | % | 2 |

| Alkali-resistivity, Weight loss (saturated cement solution, 80℃, 200 hours) |

% | ARG Fiber : 0.8 (E Glass Fiber:10.5) |

| Acid-resistivity, Weight loss (10% HCl, 80℃, 90 hours) |

% | ARG Fiber : 1.6 (E Glass Fiber : 42.9) |

| Acid-resistivity, Weight loss (10% H2SO4, 80℃, 90 hours) |

% | ARG Fiber : 1.2 (E Glass Fiber : 42.0) |

※The above values are only advisory, not guaranteed values.

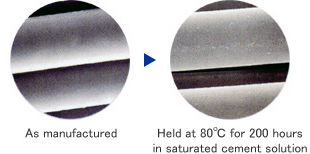

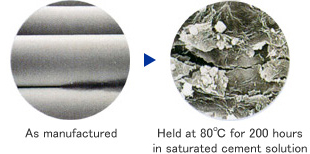

Alkali-resistivityComparison of Alkali Erosive Attack(SEM-photographs) |

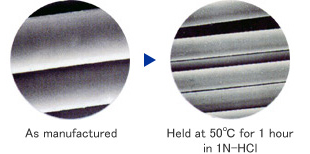

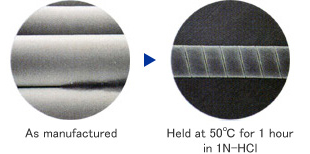

Acid-resistivityComparison of Acid Erosive Attack(SEM-photographs) |

||

| ARG Fiber | ARG Fiber | ||

|---|---|---|---|

Well-nigh perfect |

Well-nigh perfect |

||

|

(COMPARE TO LESSER "E Glass Fiber") |

(COMPARE TO LESSER E Glass Fiber) |

||

No trace of its original form |

Damaged at even intervals |