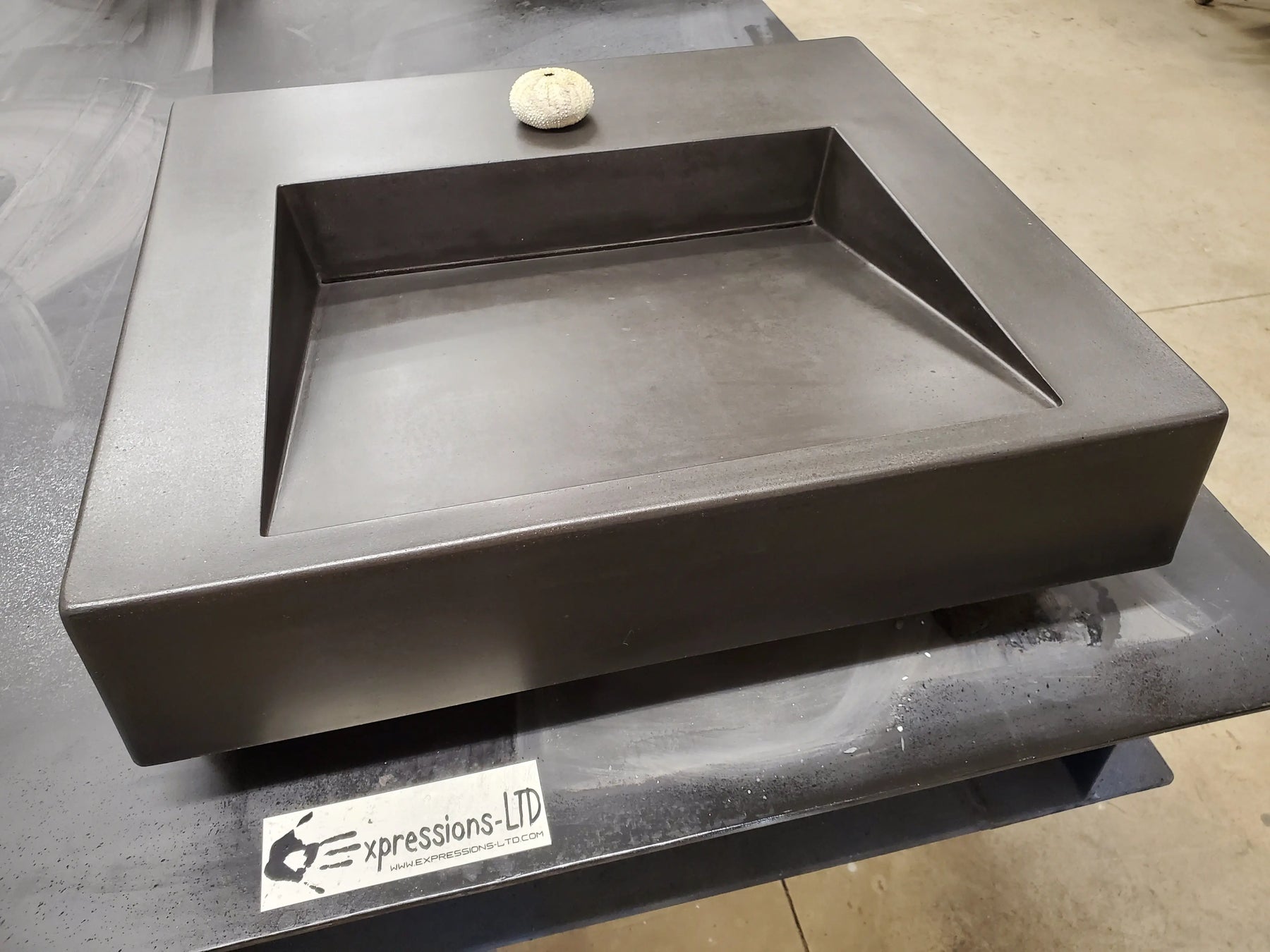

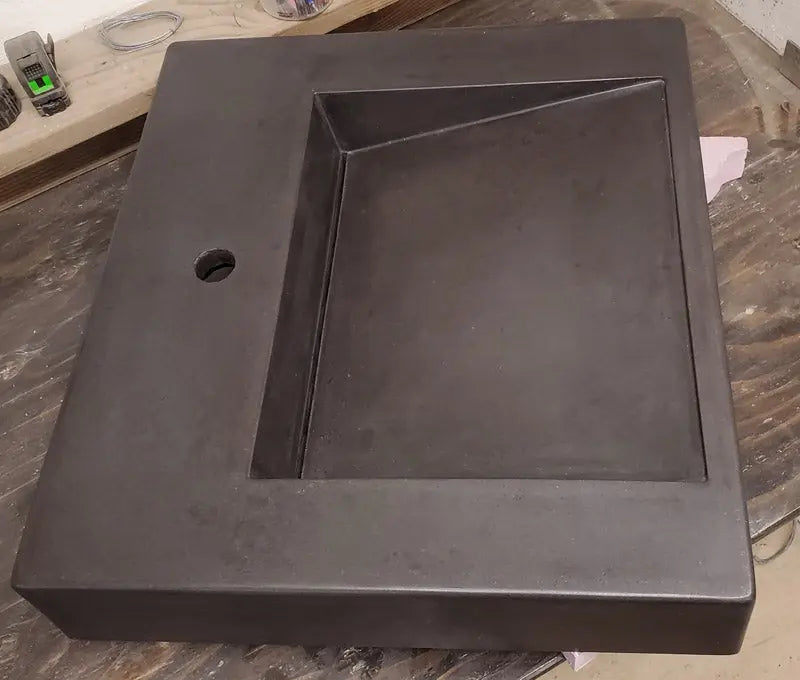

Concrete Sink Mold SDP-52 ADA Shallow Ramp Tray (24"x22"x5")

Quantity:

Fast Ship: Usually takes 1-2 business days to ship out.

Ships from Utah (Click for average Ground delivery map )

)

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Ships from Utah (Click for average Ground delivery map

)

)

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Concrete Sink Mold SDP-52 ADA Shallow Ramp Tray (24"x22"x5")

- Our SDP (Super Durable Polyurethane) Line of Sink Molds are made from the highest grade Polyurethane Rubber. Won't chip and crack like fiberglass, and much easier to get out of concrete after casting. A lifetime of reusability.

- The ADA Shallow Ramp Sink Mold Tray for concrete sink fabrication.

- A unique single part mold- Just fill this mold up with concrete, and trowel the bottom of the sink flat. When cured, flip over and pop out the concrete sink.

- Vessel Molds can easily turn leftover concrete into revenue earning concrete sinks.

- Slot Drain Style drain. Plexiglas piece included with Mold to use for creating the slot drain.

- Each Mold comes with one reusable Plexiglas Slot Drain piece. The ends of the plexiglas can be cut easily on a chop saw, to the desired angle. Angled ends on the slot piece will make removal of it from the finished concrete easier.

- All our molds have Lifetime Guarantee against defect. This Guarantee does not cover misuse of the Molds (Dropping the Mold, Prying the Mold out using a screwdriver, Driving onto it with a truck tire... etc.).

- Expressions LTD will not be held liable for any damage, misuse, or collateral damages resulting from use of any of our products. If there is a flaw or defect with a product, we will fix or replace the product.

Specifications- Concrete Sink Mold SDP-52 ADA Shallow Ramp Tray (24"x22"x5"):

- Length: 24" (Across)

- Width: 22" (Front-To-Back)

- Depth: 5" (At Edge)

- Inside Sink (Shallow Ramp): 17"x14"x3"

- Back of sink (faucet area) is 7"

- Sides have at least a 5° slope to ensure Mold removal from concrete

Mold Use:

- Watch videos of Mold Setup, Casting, and De-Molding/Removal on our YouTube Video Page.

- View Basic Sink Mold Instruction

- Wax the mold, appling 3-5 coats of Mold Release Wax to the mold, lightly buffing between coats once it hazes.

- Apply a thin coat of Rubber Safe Form Release to the Mold just prior to casting the concrete piece.

- Install the included plexiglas 'Slot' piece onto the drain area with silicone.

Concrete Casting:

- Various methods can be used to cast the concrete piece. View our Concrete Recipe section for tips on concrete mixes.

- GFRC: Cement and fiberglass is sprayed on and hand packed into the form and around the sink.

- Wetcast: Oatmeal consistency concrete is placed in form and vibrated.

- Hand Packed: A drier concrete mix is hand packed into the Mold. A second step after de-molding will fill the voids with cement slurry, usually of a different coloring.

- Any voids in the finished concrete can be filled using a Cement Slurry.

- Mix your own slurry by mixing Portland cement, Cenospheres, and water (or water/Polymer mix).

Mold Removal:

- If the steps above were followed for the Mold Setup, then most Molds will usually pull out of the concrete with little effort.

- This 'vessel' style sink is easiest to remove the concrete from the mold by flipping the whole piece over, and place something soft like pieces of foam under the sink (concrete). Then shim around the edges so the rubber mold part is raised up about 1/4" above the foam, and then leave and let gravity do the work. Eventually the concrete's weight will pull it down, out of the mold and rest on the foam pieces you set there to catch it.

- If the mold is difficult to remove, try:

- Compressed air shot around the Mold rim will break the suction holding the Mold in the concrete.

Clean-up and Care of The Concrete Sink Mold SDP-52 ADA Shallow Ramp Tray (24"x22"x5"):

- Clean Mold with a sponge after each use. Any dried cement residue can be removed with a scotch-brite pad (as outlined above in the Mold Setup section. A light muriatic acid wash (20:1, 20 parts water to 1 part muriatic acid) can also remove cement scale.

- Waxing and buffing the Mold after cleaning it use is recommended to protect the Mold until its next use.