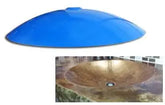

Concrete Sink Mold SDP-51 Shallow Dish Bowl (19"x3.5")

Quantity:

Fast Ship: Usually takes 1-2 business days to ship out.

Ships from Utah (Click for average Ground delivery map )

)

Ships from Utah (Click for average Ground delivery map

)

)

Concrete Sink Mold SDP-51 Shallow Dish Bowl (19"x3.5")

- Our SDP (Super Durable Polyurethane) Line of Sink Molds are made from the highest grade Polyurethane Rubber. Won't chip and crack like fiberglass, and much easier to get out of concrete after casting. A lifetime of reusability.

- The 'Flying Saucer' Sink Mold for concrete sink fabrication.

- This is a shallow sink, round design.

- Small style drain for bathroom lavatory size drains.

- Create a seamless integral concrete sink and counter top, or form around to create a vessel sink.

Specificaitons- Concrete Sink Mold SDP-51 Shallow Dish Bowl (19"x3.5"):

- Diameter: 19"

- Depth: 3 1/2" (At Drain- 3 3/4" including drain flange)

- SDP-51 is our "Flying Saucer" Sink Mold. It's a very shallow and wide round dish or bowl style mold. Makes a great integral countertop and sink, or form up a box around it and make a stand-alone vessel sink very easily. Can also be used to make bird baths, fountain bowls, firepits.

Mold Use:

- Watch videos of Mold Setup, Casting, and De-Molding/Removal on our YouTube Video Page.

- A basic Sink Mold Instruction sheet is available here.

- When planning, remember to add 1" - 2" to each side of the sink to your measurements, to account for the concrete thickness on the sides of the finished sink.

- Apply 3-5 coats of a Mold Release Wax to the mold, lightly buffing between coats once it hazes.

- Apply small amounts of silicone to the Mold's bottom, and set in place in your form. Allow silicone to dry.

- Screws can be used to secure the Mold if necessary. Using screws of the appropriate length, screw through the bottom of the form, up into the bottom of the Sink Mold.

- Run a smooth silicone bead around perimeter of the Sink Mold, where it meets the form base (using a tool such as our Caulking Ball Tool makes this process very clean and easy).

- Apply a thin coat of Rubber Safe Form Release to the Mold just prior to casting the concrete piece.

Concrete Casting:

- Various methods can be used to cast the concrete piece. View our Concrete Recipe section for tips on concrete mixes.

- GFRC: Cement and fiberglass is sprayed on and hand packed into the form and around the Mold.

- Wetcast: Oatmeal consistency concrete is placed in form and around the Mold and vibrated. A simple box should be built around the Sink Mold, to contain the concrete during this process.

- Hand Packed: A drier concrete mix is hand packed into the form and around the Mold. A second step after de-molding will fill the voids with cement slurry, usually of a different coloring.

- Any voids in the finished concrete can be filled using a Cement Slurry.

- Mix your own slurry by mixing Portland cement, Cenospheres, and water (or water/Polymer mix).

Mold Removal:

- If the steps above were followed for the Mold Setup, then most Molds will usually pull out of the concrete with little effort.

- If the mold is difficult to remove, try:

- Compressed air shot around the Mold rim will break the suction holding the Mold in the concrete.

- Most Molds can be pushed out of the concrete by removing the drain piece, and pushing the Mold out through the drain slot.

Clean-up and Care of The Concrete Sink Mold SDP-51 Shallow Dish Bowl (19"x3.5"):

- Clean Mold with a sponge after each use. Any dried cement residue can be removed with a scotch-brite pad (as outlined above in the Mold Setup section. A light muriatic acid wash (20:1, 20 parts water to 1 part muriatic acid) can also remove cement scale.

- Waxing and buffing the Mold after cleaning it use is recommended to protect the Mold until its next use.