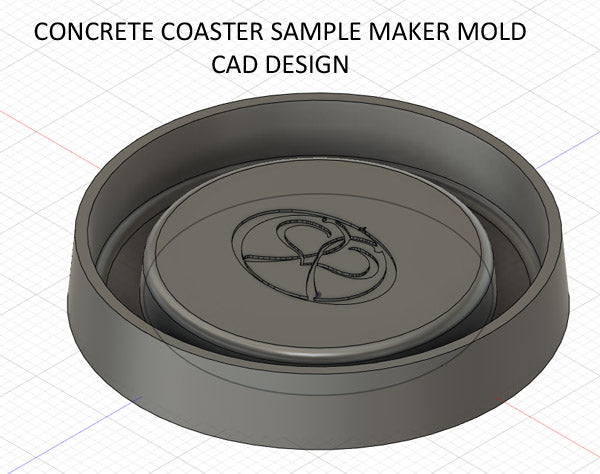

Custom Coaster Logo Mold - Make Concrete Samples

Style:

Style

Quantity:

Shipping: This Product can take 5 to 10 business days to ship out.

Custom Coaster Logo Mold - Make Concrete Samples

- Custom made mold for you to use to make concrete coasters (drink holders) or just samples to give away.

- Don't waste that leftover concrete mix, instead throw it into molds to make samples! For concrete, having samples to show color options, sealer options, is vital to a business model. Brand your samples with your company logo/information, rather than just a plain sample.

- Finished Concrete Pieces: 3.25" Diameter x 0.5" Thick.

Specifications for Custom Coaster Logo Mold

- We need your layout. You can place your order, and then reply to the order confirmation you receive and attach the info we need, and any logo file. You can also email us direct at sales@expressions-ltd.com.

- If you have a logo, we need that in high quality/resolution, and in just black and white. Then we need what text you want. Ideally a layout in a picture or typed out exactly how you want, font used, etc. We want to make you what you want, but don't really want to tell you what you want. That's for you to come up with, and just let us make you the mold...!

- For Logos/Designs: If you do NOT have a good image to send us, but have a low resolution, color, or fuzzy picture you need us to use, we will contact you about costs to clean up most art images (usually between $40-$80).

- We charge you a mold fee. This includes our CAD programming, building the molds we need here, and then we can make the rubber parts to send you.

- Once you pay this mold fee, that's it. If you come back to us a year from now and want more rubber molds made, you won't need to pay that fee again. We'll save your mold here and just pull it out and make you more parts.

- Use the options above to pay the mold fee and Add to Cart. Then return to this page and change the selection to the Coaster Mold, and now you can select the quantity of molds you want made and shipped to you.

- For these molds, we use a soft, pliable rubber that is great at showing fine detail. Please keep in mind that softer rubbers can potentially rip easier, so just be a little careful when using them and they will last for a really long time.... hundreds of uses if not thousands.

How to Use Custom Coaster Logo Mold to Make Concrete Samples

- Before filling up with concrete (or whatever product you are using) a release agent should be used. For concrete, and probably most other uses, the Crete Lease (sold here) will work well. This kind of release needs to be just a super fine coat. So use a little foam brush after lightly spraying it and wipe all the release back off the mold. Too much release oil will just make little air pinholes.

- Fill up, or spray in (if using GFRC).

- For better end result, vibrate the molds.

- For near perfect results, consider using a small pressure chamber (like these on Amazon). You can set the molds in the chamber, set up some racks inside if doing a lot of molds at once, and then just hook up an air compressor to it and put around 30-40psi into the chamber, and that's it. Leave in there until the product is cured (1-2 days for concrete is usually enough) and then let out the pressure and open up and demold.

- Care should be taken to not demold too early. Concrete for example will be hard enough to take out of the mold usually the next day (depends on mix using). But being set up enough to seem solid is not the same thing as being strong enough that the fine detail/lettering being strong enough that it won't break off and be stuck in the mold.