Decorative Crushed Aggregate for Concrete - Mirror Glass

Size:

Size

Quantity:

Ships from Illinois (Click for average Ground delivery map

)

)

Shipping: This Product can take 5 to 10 business days to ship out.

Ships via FedEx/UPS only

Ships via FedEx/UPS only

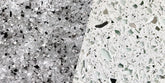

Decorative Crushed Aggregate for Concrete - Mirror Glass

- Crushed Decorative Glass, Mirror Glass

- Mirror glass is made from one-sided mirror, and is often used as an aggregate to blend with other aggregates, adding a reflective element.

- All #2 in size, 1/4" to 3/8" pieces

- Sold in 5lb, 20lb and 50lb sizes

- 1 lb. nicely seeds about 4 sq ft. Coverage will vary based on personal taste and density desired

- Decorative aggregates are among the long list of reasons that concrete countertops are the best choice for creative expression compared to other countertop choices

- By seeding the aggregates how and where you desire, then grinding and polishing, you have total control over the design process. It is so easy to "make it your own."

- Our choices of recycled glass and crushed marble give you a spectrum of color to work with

- Decorative aggregates, such as colored glass or crushed stone, can add a great uniqueness to a concrete countertop. Aggregate is not very difficult to use and it creates a total custom look. However, it does require more work that just pouring the concrete because you need to expose the aggregate through careful grinding and optional polishing

- Other colors may be available for special order, contact us if needed

Decorative Crushed Aggregate for Concrete - Mirror Glass

- There are three basic ways (ranked from easiest to most difficult) of getting the decorative aggregate into concrete piece:

1. Mix all of the decorative aggregate in with the concrete.

- Easiest method- Since the decorative aggregate is mixed into the concrete, all surfaces will look the same. In addition, the average spacing of the aggregates is more uniform. It does take the most aggregate though, up to 10 pounds of aggregate per 50 lb concrete mix bag.

2. Placing aggregate in the bottom of the mold when precasting (pouring upside down)

- Second easiest method- This method is very useful when you want a specific pattern or look to the finished design. The aggregate is usually held in place at the bottom with a bit of spray glue so it does not move when the concrete is poured in.

3. “Seeding” the aggregate in the top of the concrete once the forms are filled.

- Third easiest method- This method is similar to the bottom seeding except you need to time it right so that you can float the aggregate carefully into the surface (actually push it just below) so that when it cures, you can expose it through grinding. The key here is that you must be quite good at floating and finishing the concrete to be very flat so that when you grind, you are not dealing with undulations in the surface. This method only requires 1-2 lbs of decorative aggregate per bag.