Glass Fiber Reinforcement - Chopped Fiber AR Anti-Crak® 3mm

Size:

Size

Quantity:

Fast Ship: Usually takes 1-2 business days to ship out.

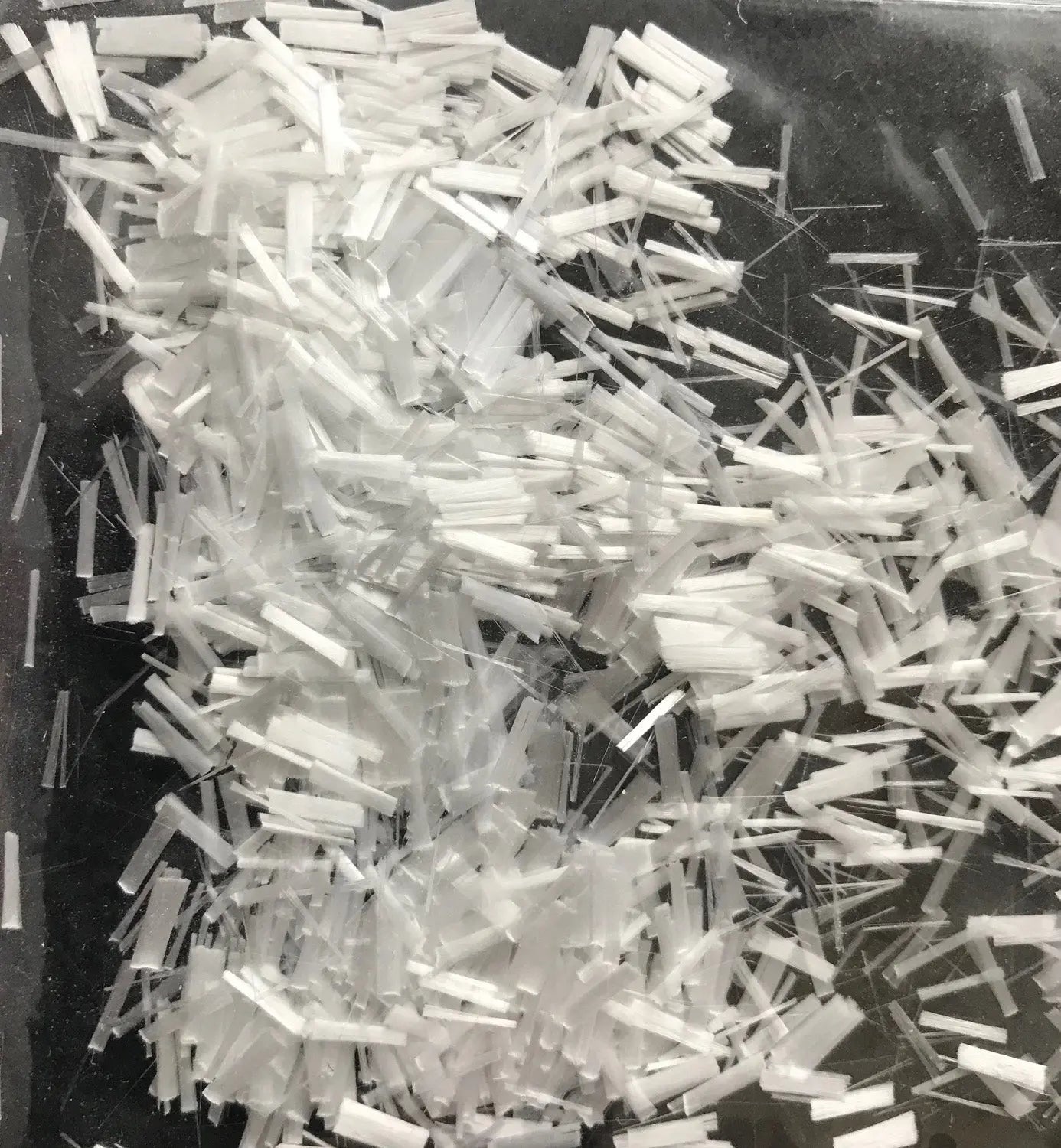

Glass Fiber Reinforcement - Chopped Fiber AR Anti-Crak® 3mm

- This is the small fine fiber that is in most expensive pre-bagged concrete countertop mixes. Can be added to any concrete mix, but excels as a fiber additive for SCC (Self Consolidating Concrete- ie. pourable sand mixes) GFRC face coat mixes, Carving Mixes, and any other concrete surface mix where you don't want to see the larger AR Fibers (as these, sold here)

- Beware of other 'nano' fibers on the market! Avoid lower quality fiber, under many names such as 'nano fibers' that don't disperse and clump up, or that lack the zirconia needed for true AR fiber strength in concrete!

- Anti-Crak® HD (High Dispersion) in 3mm (1/8") made by Owens Corning- leader in fiber reinforcements.

- Fibers comes out as small clumps from the bag, but quickly break down to the individual 14µ filaments when mixed in concrete.

- Anti-CRAK® AR-glass fibers give the mortar a uniformly dispersed network of fibers that will significantly improve the thixotropy and the resistance to plastic shrinkage cracking.

Specifications Glass Fiber Reinforcement - Chopped Fiber AR Anti-Crak® 6mm/ 3mm

- Filament lengths: 3mm (1/8")

- 3mm size: 1lb, 2lbs, 4lbs, and 40lb Full Bag

- View Anti-Crak Data Sheet

- Glass Fiber Scrim SDS Sheet (Safety Data Sheet)

Application / Coverage Glass Fiber Reinforcement - Chopped Fiber AR Anti-Crak® 3mm

- Typical Dosage: 0.5 -1.0 lb per cubic yard of concrete (1 cu. yard = 45x 80lb bags of concrete!)

- @ 0.5% of the total weight before adding water of the concrete mix.

- Example: At 1lb of fiber per yard, you would use 1/45th of 1 pound of fiber per 80lb concrete mix, which is 10 grams and comes out to be a Large Heaping Tablespoon. This fiber goes a long way!

- Pre-Mixing the fiber into your mix water will help break them up. Pre-mixing with dry cement is another way to disperse the fiber-- Take some cement and a small container or bucket, and a mixing drill (such as for paint) and blend the fibers into the cement, then add the cement to your concrete mix and finish mixing. Stop mixing and test some sections to ensure fiber has dispersed- if clumping of fiber is found, continue mixing a until fully dispersed.

- Concrete and GFRC mix recipes can be found in our Concrete Recipes section.

- When mixing in Ready Mixed Concrete (trucks), the Fiber can be added into the truck on the job site, and mixed for 5 minutes to break up the fiber and disperse it before starting the pour.