Z Aqua-Thane G40 Concrete Countertop Sealer, Gloss Finish

Quantity:

Ships from Pennsylvania (Click for average Ground delivery map

)

)

Shipping: This Product can take 2 to 3 business days to ship out.

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Z Aqua-Thane G40 Concrete Countertop Sealer, Gloss Finish

- Z Aqua-Thane G40 is a water-borne, two-component, self cross linking polyurethane coating. It exhibits a high gloss finish and offers superior stain, abrasion and chemical resistance. The durability makes this sealer ideal for high-traffic areas. Z Aqua-Thane G40 is safe for indoor or outdoor use.

- Provides a glossy, abrasion resistant finish.

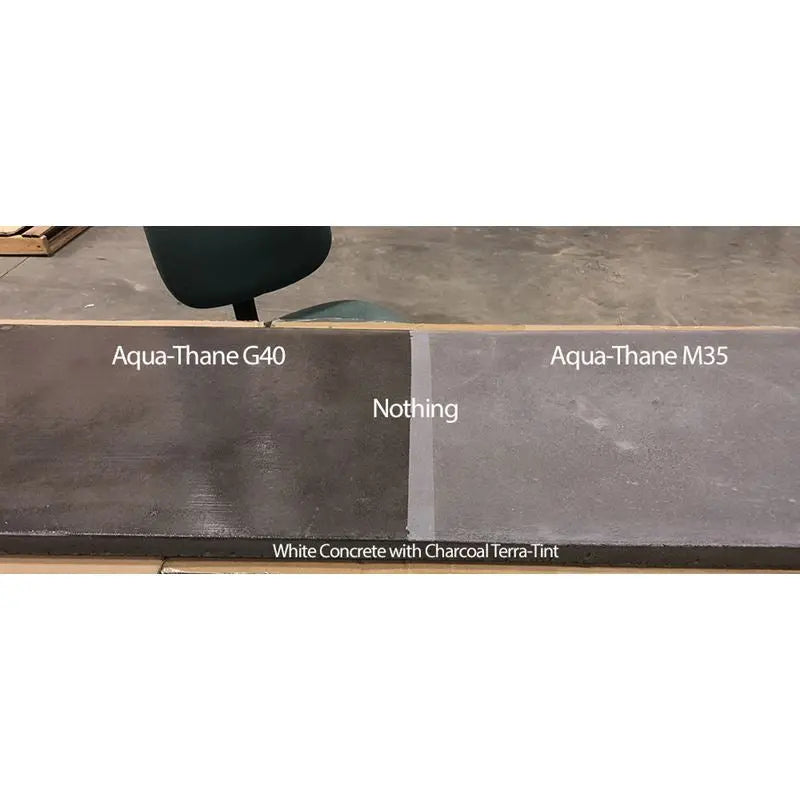

- Will provide darkening "wet look". Amount of darkening will depend on porosity of concrete. Always test on sample to confirm results first.

- Excellent chemical resistance.

- UV Resistant

- Fast drying

-

Surface is 100% food safe once cured.

- Coverage - 50-75 sq. ft. @ 2 coats (one 1.5 qt. kit)

- Aqua-Thane G40 vs. Aqua-Thane M35 - The G40 has a semi gloss finish and will darken or "wet out" the concrete very similar to when water is applied to an unsealed surface. The M35 (sold here) has a matte/ satin finish with very slight darkening on colored concrete.

- Note: If a darkening effect with a satin finish is desired one coat of the G40 can be used first to darken the concrete followed by 1-2 coats of the M35 to create the satin finish. They can also be used in reverse to create a gloss finish without any darkening. For this start with at least 2 coats of the M35 (then test with water to make sure it is well sealed and no G40 will get through to the concrete), then apply 1 coat of the G40 to add a gloss layer.

Z Aqua-Thane G40 Concrete Countertop Sealer, Gloss Finish Instructions

- Surface Prep: New concrete must be completely cured before applying this sealer. Any moisture remaining in the concrete can cause adhesion issues. You can check the concrete with either a moisture meter or by taking several 6x6 inch sheets of clear plastic and thoroughly taping it to the surface completely around the edges. If after 24 hrs the plastic is dry, it is assumed there are not hydrostatic pressure problems. If acid stains or washes are used, the concrete must be completely neutralized back to a pH of 7. On all new hard troweled concrete a light sanding with 100-200 grit sand paper is recommended to open the surface and promote adhesion. On burnished, highly polished or concrete cast against smooth surfaces, additional sanding or acid etching may be required for the best adhesion properties. On textured or stamped concrete, no additional steps are required but in all cases concrete should be clean and 100% free of all dust, debris, or previous coatings.

- Mixing: Mix exactly 2 parts of A to 1 part of B. Mix thoroughly with a paint mixing stick and always scrape the sides of your mixing container to ensure a uniform mixture. Mix adequately for 2-3 minutes. Failure to properly mix components may result in adhesion or hardness issues. Pot life of mixed components is roughly 2-3 hours at 75ºF.

- Application: Concrete surface should be between 55ºF and 85ºF. In smaller areas such as countertops, a 1/4” nap roller or a micro-fiber applicator pad is recommended. Product should be applied in a thin even coating. Do not allow to puddle in low areas. Back rolling may be necessary to control thickness and guarantee a uniform coating. Two coats should be applied for sufficient protection. On rough or more porous concrete additional coats may be needed. Always test with water to confirm concrete is adequately sealed. Recoat time is between 6-12 hours at 75ºF and the first coat should be tack free. If this window is missed, the first coat may have to be lightly sanded with 300 grit paper before applying a second coat.

**Avoid sticking tape to sealed concrete. Chemical bonds can form between glue and sealer which can be strong enough to pull off sealer and stain. If this happens, these areas can normally be sanded and spot fixed**