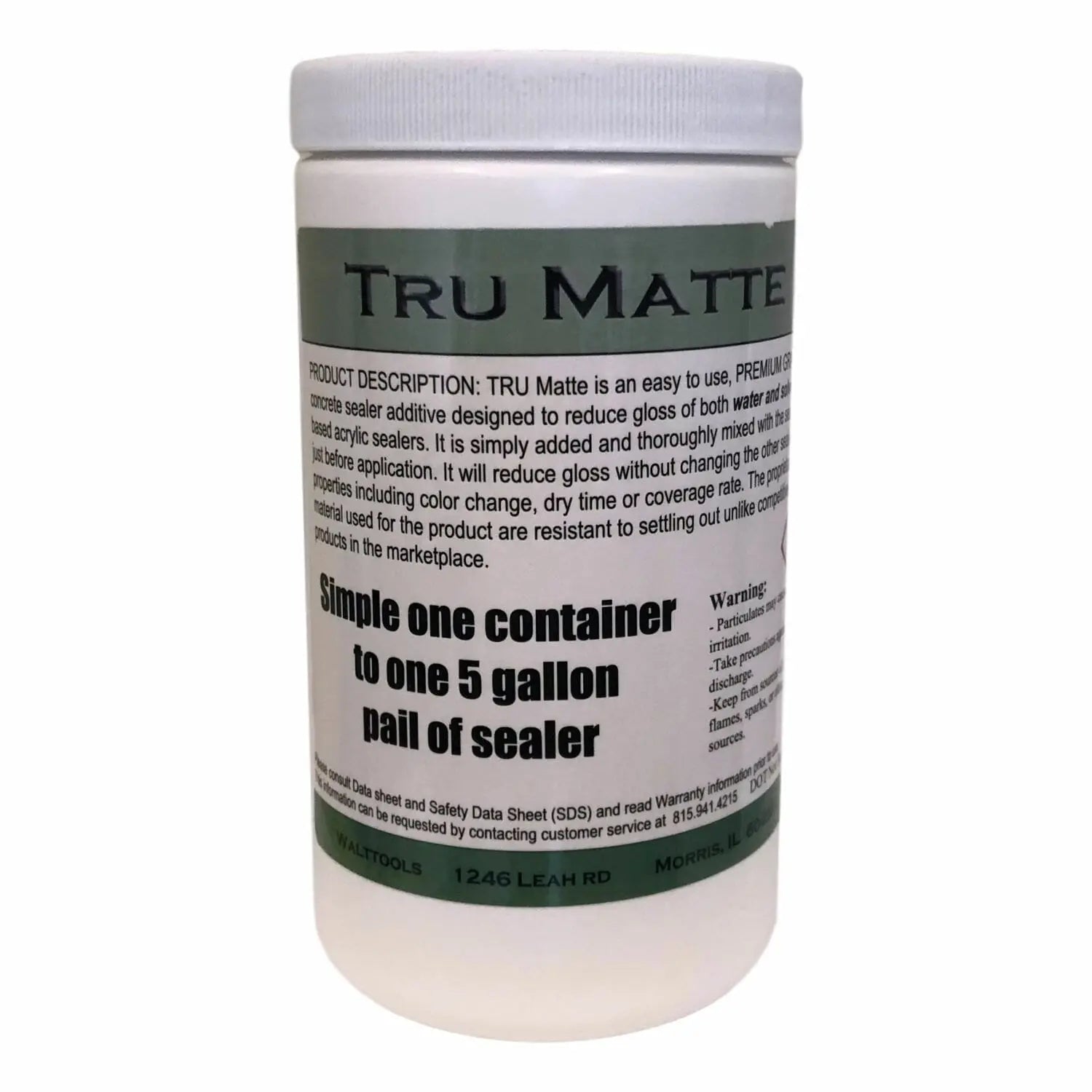

Matting Agent - Gloss Reducer for Concrete Sealers and Coatings

Ships from Illinois (Click for average Ground delivery map

)

)

Shipping: This Product can take 2 to 3 business days to ship out.

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Product Description

TRU Matte is easy to use, PREMIUM GRADE, concrete sealer additive designed to reduce gloss of both water and solvent-based acrylic sealers. It is simply added and thoroughly mixed with the sealer just before application. It will reduce gloss without changing the other sealer properties including color change, dry time, or coverage rate. The proprietary material used for the product is resistant to settling out, unlike competitive products in the marketplace.

Tru Matte is made to be used in acrylic sealers such as Stampsheen, Stampsheen 350, Stampsheen H2O for reducing or eliminating gloss:

- For semi-gloss/satin look: ONE Pound (16 oz by weight) container for 5 gallons of sealer (or about 3 oz. per 1 gallon of sealer)

- For full matte look: TWO 16 oz containers for 5 gallons of sealer (or 6 oz per gallon of sealer)

- If doing less than a full container, the material should be weighed out accordingly for consistency with batches. One gallon should take just under one kitchen cup

- If doing multiple coats of sealer, a matting agent should be applied just to the final coat

- It is always recommended to test sealer and matting agent load on a test area of any job before proceeding on the complete job.

- Add matting agent to the desired amount of sealer and mix for two minutes with a medium speed using a Jiffy style mixing head. DO NOT HAND STIR MATERIAL AS IT WILL LIKELY NOT BLEND FULLY. Though Tru Matte stays suspended for a long period of time it is always recommended to re-agitate anytime you pour more material from the original container.

**Matting Agent can also be added to solvent based Polyurethane coatings. To use, mix the matting agent into the part A of the coating first, and then once mixed, add the part B and mix per the coating instructions.