Decorative Vinyl Chips for Epoxy Floors

Ships from Illinois (Click for average Ground delivery map

)

)

Shipping: This Product can take 2 to 5 business days to ship out.

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Decorative Vinyl Chips for Epoxy Floors

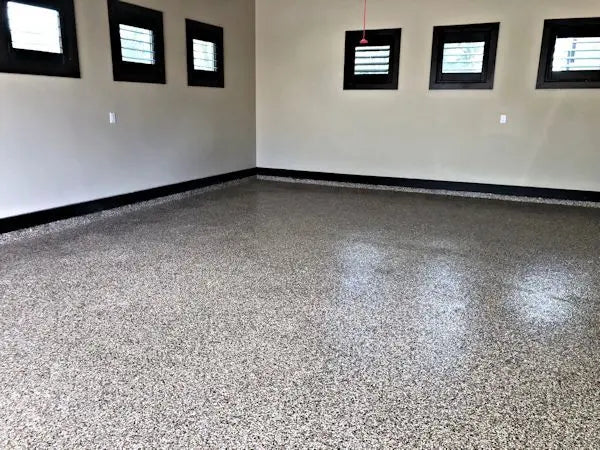

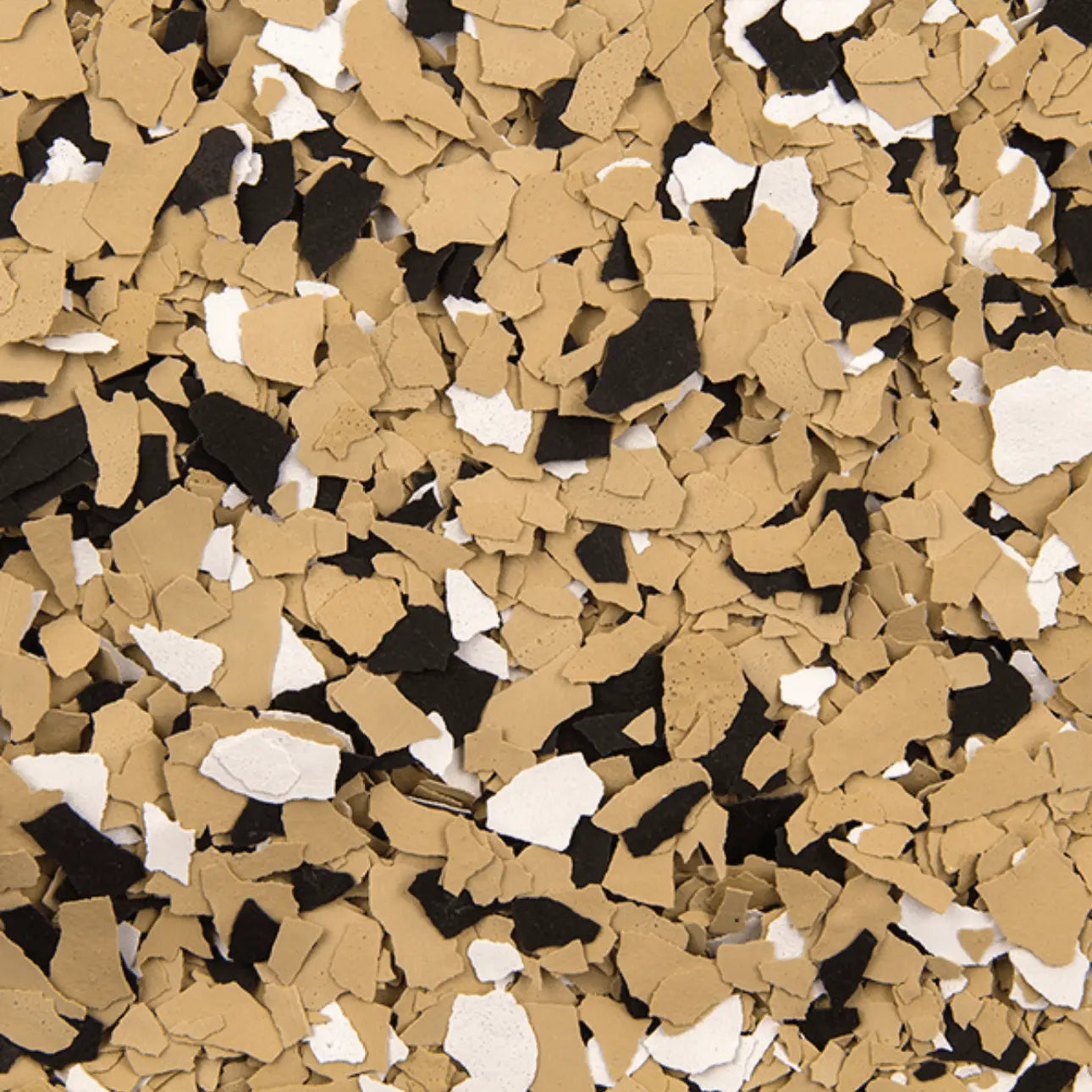

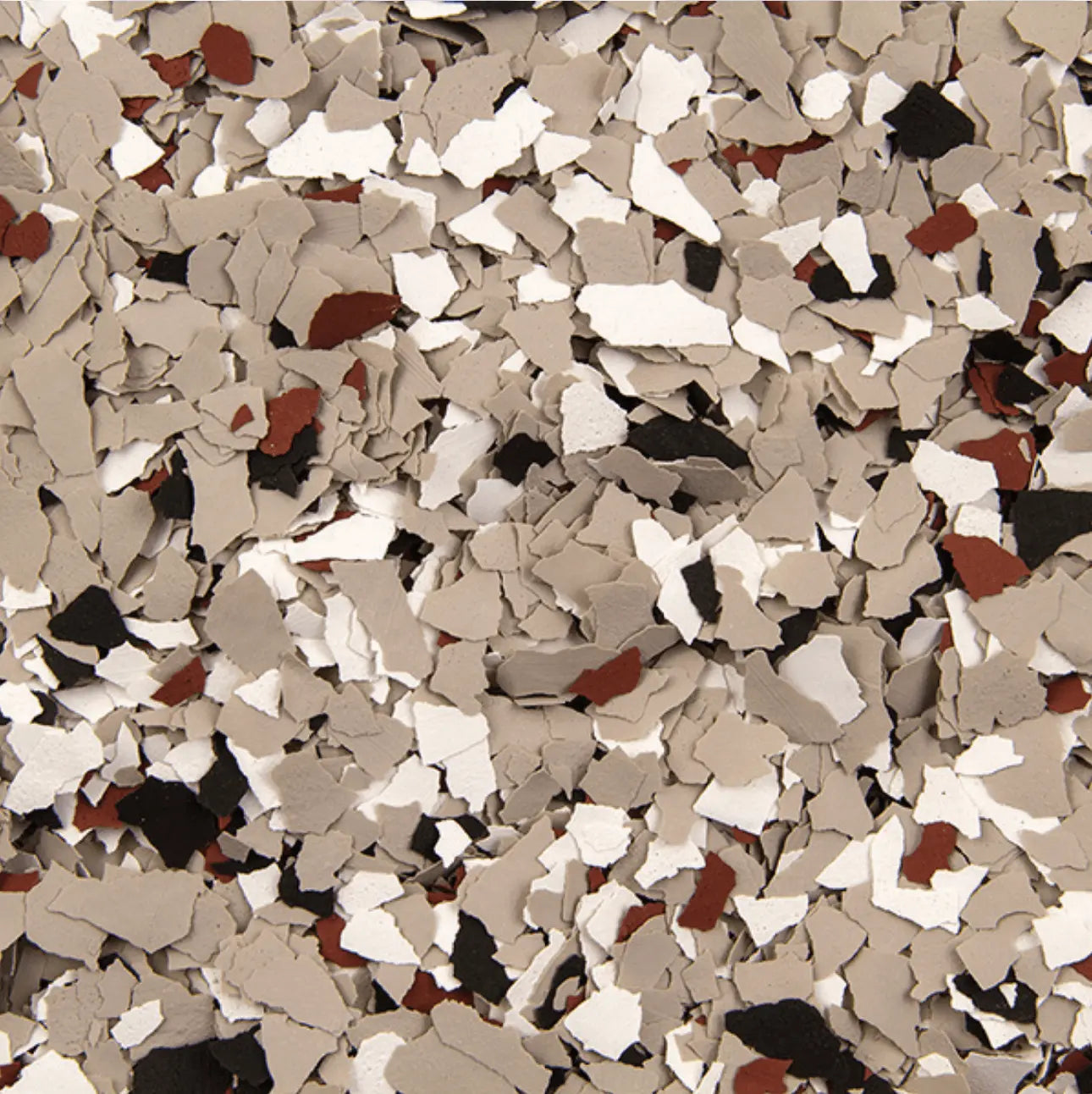

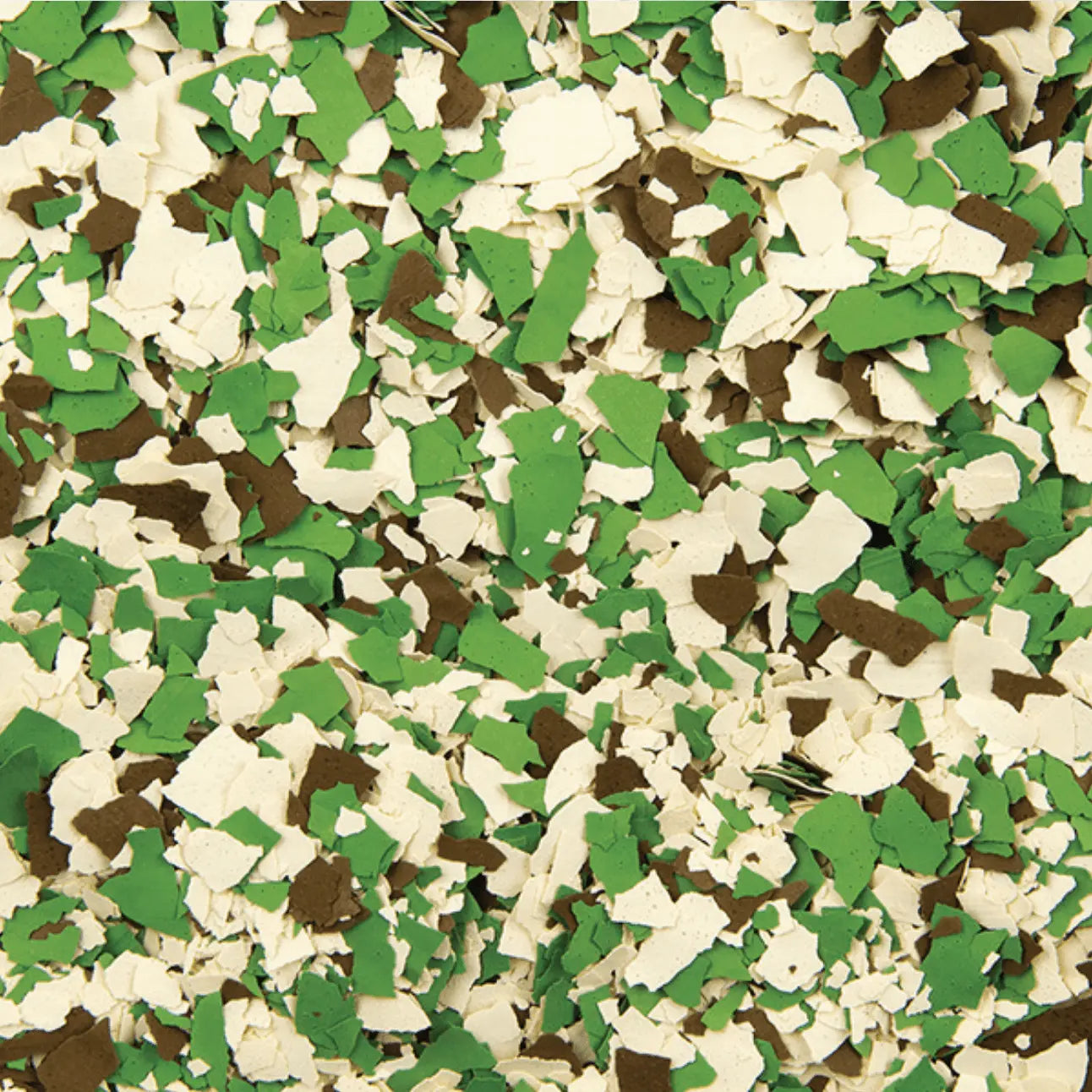

Vinyl Chips are a decorative high-performance broadcast. 1/4" (6mm) flakes of vinyl, blended into a variety of color blends. When broadcast onto a resin coat, typically an Epoxy such as TI Epoxy HP (sold here) and then top coated with a durable product like Aliphatic Urethane -sold here-, this type of floor will ensure excellent wear-ability characteristics with great stain and chemical resistance. They require minimal maintenance. Chips come in several color blends and can be used in a partial or full broadcast, or even combined with other broadcast media such as Quartz Sands for a unique look.

Typical applications include: garages, showrooms, lobbies, locker rooms, retail stores, and similar institutions.

Coverage Information:

- Sold in 25lb Boxes

- For full broadcast: 6-10 sq. ft./lb

- For partial broadcast: 25-200 sq. ft./lb

Please Note: Coverage rates vary depending on customer preferences and application techniques. We cannot guarantee any coverage rate of broadcast media due to variables. To be safe, order a bit extra if unsure.